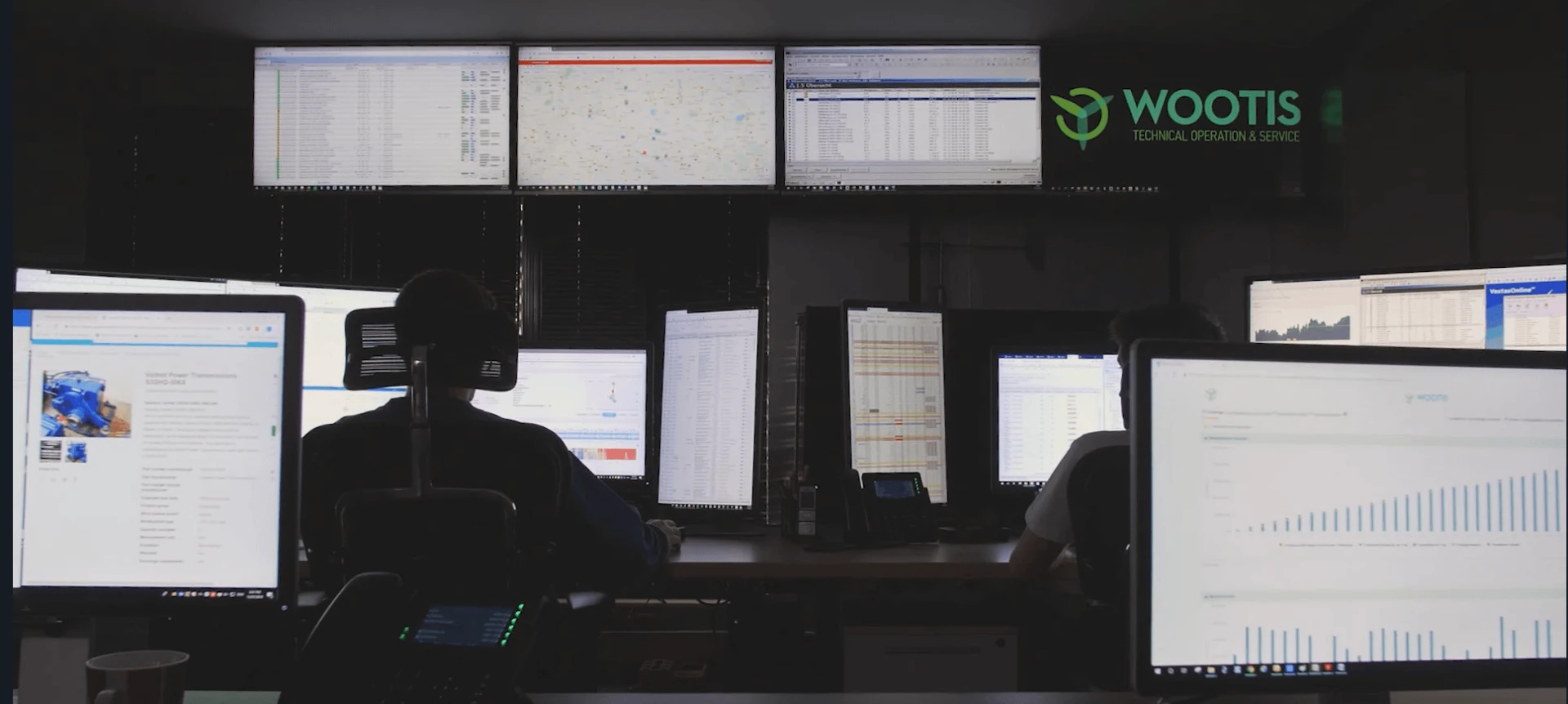

Monitoring data is only a small part of what the live remote monitoring department does. In fact it does much more. We meticulously collect as much data as possible and then analyze it to achieve better performance, greater availability and reduced wear and tear on your installation.

Wind Farms

REMOTE MONITORING

We monitor Wind Farm assets on a daily basis, 24 hours a day, 365 days a year, thanks to our unique software and our qualified team. We constantly store all required data, and through technical analysis in partnership with the Technical Management department, we ensure that your investment yields the highest possible profits.

We deal with the ensuing faults as soon as possible in order to reduce downtime of the plant to the minimum, either through remote manipulations or, if this is insufficient, by alerting the investor's representative and/or the appropriate service team for an on-site visit.

Performance Improvement

Fault Analysis

Our extensive experience has taught us that in 60% of cases, a simple reset is all that is required to resolve an error. Such errors typically continue to considerably reduce the output of the stations and, as a result, the expected revenue, in facilities that are not monitored 24 hours a day, seven days a week. We strive for, and are happy to accomplish, a first reaction time of less than 15 minutes from the time the production unit is shut down to the time it resumes operation.

Constant Communication

The live remote monitoring center serves as the technical and commercial hub for the technical and commercial management of your production station. Its purpose is to provide any third party with the necessary information on the stations, including the Network Administrator and the RES and HCHP Aggregator, who works with you on a regular basis or in an emergency.

MAINTENANCE AND TROUBLESHOOTING

Wind turbines are extremely expensive electromechanical installations that are subject to all weather conditions. We understand how critical it is for your assets to constantly perform flawlessly, regardless of the adverse weather conditions. We also know that good maintenance has a significant impact on the success of a RES project's operation at every stage of its life cycle. Downtime is keptmaintained to a minimum with adequate maintenance and preventive measures. Our employees' prompt response in the event of mistakes or malfunctions is an additive contributing factor.

Proactive and Reactive Maintenance

Many failures can be prevented if a power plant is adequately maintained by a team of skilled experts. The facilities are proactively maintained twice a year. All essential work is completed in accordance with the manufacturer's and installer's standards. In addition, signs of problems can be identified that could be detrimental to the installation in the future. In any case, and in order to maximize the operational time of RES projects, the company guarantees the intervention of the crew for damage repair, following the emergence of an error, in a short period of time, which varies depending on the location and size of the project, but never exceeds 36 hours.

Electrical and Mechanical maintenance

Wootis offers sophisticated equipment suitable for carrying out any preventive maintenance work on your power plants electromechanical installations. The work is carried out in compliance with the manufacturer's manual instructions and standards, as well as the principles of technique and science and in the context of international practice.

Maintenance of Supporting Facilities

We also provide in advance for the secondary facilities of your power plants, such as the access roads, the foundations and the rest of the structural elements of the park.

Additional upgrade work

Our many years of experience in the field of RES projects has made us pioneers in the use of technologies and the discovery of technical solutions, when it comes to optimizing operation and energy efficiency, maximizing resource utilization and establishing the possibility of direct televisions and remote controls via telemetry.

TECHNICAL MANAGEMENT

In order to ensure the maximum continuous operating time of the Wind Parks, as well as their maximum technical availability and production and consequently increase their lifespan, it is necessary to organize workflows and manage the right staff effectively. The technical management department coordinates all stakeholders, from the live remote monitoring department and the maintenance team to the project owner and third parties, so as to ensure that information is transmitted to the relevant party in the shortest time possible and the uninterrupted operation of RES projects.

Supervision of the power plant

Because each customer has their own requirements, desires and goals, we choose to co-decide with each other the terms and the framework of proper operation for each installation. In addition, we adjust the schedule of maintenance and site visits, depending on the particular requirements of each station and the prevailing climatic conditions of the area. Based on the specifications of each manufacturer, the needs and the particularities of each installation, the regular maintenance program for each installation is regularly prepared and checked for its observance and functionality. The contractual obligations in case of a third party Maintenance Service Provider are monitored and analyzed and the necessary support is provided to the project owner to substantiate the claims against the third party Maintenance Service Provider or to involved organizations, such as the Grid Administrator and the Insurance Companies.

Reporting and performance analysis

The data provided by the live remote monitoring department is analyzed in technical reports prepared on a monthly basis for each installation and includes power generation, installation availability, production loss and a list of events and errors, according to the installation measurements. Thanks to the direct recording of data in an event book (logbook) and based on the information provided by the manufacturer of each installation, it is possible to conduct analyses and compile proposals for preventive actions against the occurrence of errors and to optimize the operation of wind farms.

Compliance to legal regulation

Compliance with the terms of the licenses on which the power plant was placed and is operating (e.g., production license, operation license, AEPO, etc.) is part of the technical management, as is their renewal on behalf of the project owner. All reports and papers created by third parties and delivered to the Wind Park’s owner are reviewed as part of the technical management service.

COMMERCIAL MANAGEMENT

The ever-increasing financial demands of wind farmsparks, related to maintaining the required liquidity to meet the needs of all stakeholders without endangering the return on investment, prompted us to incorporate project commercial management as part of our holistic strategy.

Bookkeeping

We objectively and computationally check all invoices based on offers, purchase orders, or information we have. All transactions are completed on time. We compare the energy production calculated by HEDNO / LAGIE tariffs to the production documented by the software used by the technical management department.

Financial monitoring

We organize the data chronologically and include it into your investment's workflow. This way, you'll have a better understanding of the needs and obligations related with your installation. At the same time, we carry out all of your investment-related duties with banks, government agencies, utility companies and RES Aggregators.

Financial Statements

We review the installation's cash inflows and outflows quarterly, examine financial and organizational documents and all of the installation's obligations and notify you about the financial position of your investment.

REPRESENTATION IN THE ENERGY MARKET

RES Aggregator

According to the new support scheme for electricity production by RES and cogeneration plants, RES producers will gain great incentives for competitiveness in a competitive market, while in the same time they will be held responsible for the accuracy of their production forecast and will be financially burdened in case of discrepancies between their forecasts and actual production. As a result, they must be represented by RES & HCHP Aggregators (FOSE), and Wootis can provide reliable representation services for RES and HCHP plant owners on the electricity market.

Price and Production Forecasts

In order to maximize the potential of your wind parks, we develop and employ our own software systems for RES asset management, monitoring, and 24/7 trading services. We will forecast market prices and the amount of energy produced by your parks in order to keep them competitive in an ever-growing energy market. To accomplish the greatest possible collaboration between RES Aggregator to achieve our joint aim - to reach the best possible price for your production - access to power park systems is required to retrieve production data in real time and, where possible, to remotely manage wind turbines.

Optimized Direct Participation in all Power Markets

To avoid as much financial loss as possible due to imbalances, we apply cutting-edge methodologies to forecast the production of installed RES capacity. Similarly, we use market price forecasting methodologies to optimize our participation in all of the Hellenic Energy Exchange marketplaces listed below. We use models that evaluate which market participation strategy would prove more profitable. Thus we evaluate the profitability of each of the following markets Forward, Day- Ahead, Intraday- Continuous, Balancing and Ancillary Services and decide how to spread our treaded volume across these markets. At the end of each month, we provide detailed reports on the performance of your data.

Direct and immediate payments

We manage and clear transactions on a daily basis for Day Ahead and Intra-Day marketspurchases and on a monthly basis for imbalance charges. We are in constant contact with the Hellenic Energy Exchange and the appropriate clearing houses, in order to provide direct and immediate payments to our customers on a weekly basis.

EQUIPMENT SUPPLY AND SPARE PARTS

Wootis delivers useful supporting material during the implementation of maintenance contracts and at any stage of the RES project's operation.

We keep a significant supply of spare parts on hand, which is replenished on a regular basis. Our spare parts are kept in perfect condition in our company's warehouses. As a consequence, regardless of which the manufacturing company is, we always have in your disposal spare parts for the equipment of the projects we undertake and the maintenance work. Otherwise, we can meet any demand that your wind farm may have through our collaboration with big manufacturing companies and suppliers.

Contact our people